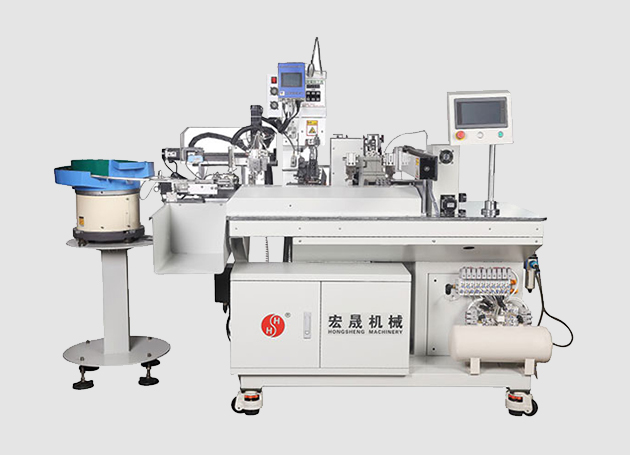

Product Name: HS-63219 Single-head back-end plastic shell thread rolling and dipping machine

Product Features

●The equipment realizes continuous automatic processing of wire drawing, cutting, stripping and rubbing the wire with tin, and stripping with the other end, hitting the terminal, and threading the wire into the plastic shell.

● The equipment mainly uses servo terminal machine, absolute value servo, precise action, simple operation, stable performance, labor saving and quality stability. .

●Using touch-type man-machine interface operation, adjustment is convenient and fast.

|

model |

HS-63219 |

|

power supply |

AC220V/50HZ (Single phase) |

| Features |

The wire is cut automatically,-the end of the wire is stripped, the wire is dipped in tin, and the other end is stripped and played with a plastic shell |

|

Production capacity |

25 lines/minute (within 100 mm) |

|

Processing wire diameter |

0.3mm²-0.75mm² |

|

Cutting length |

60mm-500mm |

| Stripping length |

1mm-10mm |

|

Length of thread rolling |

3mm- 10mm |

|

Dipping length |

3mm- 10mm |

|

Cutting accuracy |

0.5mm + cutting length * 0.2% or less |

|

Pressing ability |

2.0T |

|

air pressure |

0.6-0.7Mpa (Please use clean and dry air source) |

|

Testing device |

The wire is missing or knotted. End detection, pressure management device, whether the plastic casing is in place |

|

Dimensions |

3000L* 2300W*1600H (mm) |

|

weight |

about 500Kg |

| other |

Optional terminal visual inspection (special requirements can be customized) |