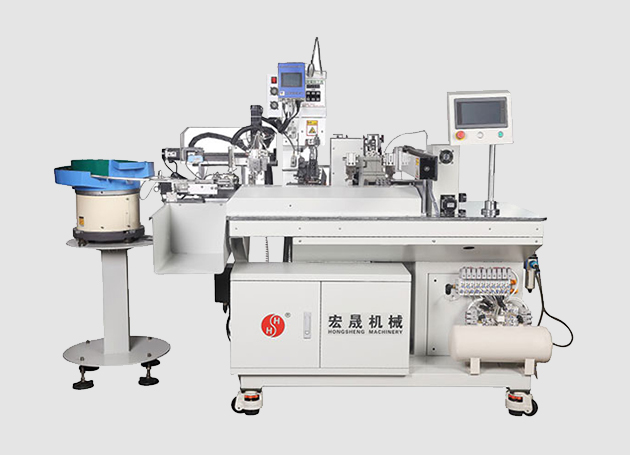

Product name: HS-62319-A Automatic tangential peeling double pressure double wear plastic shell machine

Product Features

●The equipment realizes continuous automatic processing of wire drawing, cutting, peeling at both ends, hitting terminals, and threading the wire into the plastic shell.

● The equipment mainly uses servo terminal machine, absolute value servo, precise action, simple operation, stable performance, labor saving and quality stability.

●Using touch-type man-machine interface operation, adjustment is convenient and fast.

|

model |

HS-62319-A |

|

power supply |

AC220V/50HZ (Single-phase) |

|

Features |

Wire cutting, stripping, double-end crimping, double-end plastic shell |

|

Production capacity |

20 lines/minute (within 500 mm) |

|

Processing wire diameter |

0.3mm²-0.75mm² |

|

Cutting length |

120mm- 800mm (the longer the tangent, the slower the speed) |

| Stripping length |

1mm-10mm |

|

Cutting accuracy |

0.5mm + cutting length * 0.2% or less |

| Pressing ability |

2.0T |

|

Testing device |

Wire missing or knotted, end detection, whether plastic casing is in place, pressure management device |

|

air pressure |

0.6-0.7Mpa (please use clean and dry air source) |

|

Dimensions |

2400L*2200W*1800H (mm) |

|

weight |

about 1500Kg |

|

other |

Optional terminal visual inspection (special requirements can be customized) |