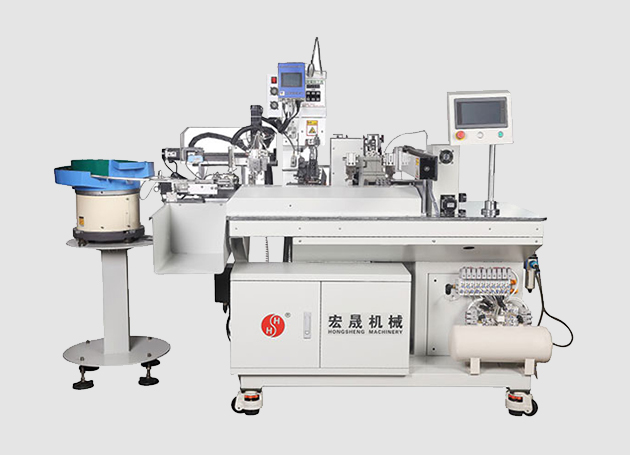

Product name: HS-61219-B Full-automatic tangent peeling single-pressure single-through plastic casing machine

Product Features

●■This equipment is the first in the country to realize continuous automatic processing of wire drawing, cutting, peeling, crimping of terminals, wearing plastic shells, and then PVC pipes and heat shrinkable tubes;

● The device is mainly equipped with servo motor, with precise action, simple operation, stable performance, labor saving, and quality stability;

●Using touch-type man-machine interface, adjustment is convenient and fast.

|

model |

HS-61219-B |

|

power supply |

AC220V 50HZ (Single phase) |

| Features |

Single-end terminal, single-end plastic shell, six-color wire is used in the same plastic shell, and PVC pipe and heat-shrinkable tube are sleeved on the six-color wire |

|

Production capacity |

20 pcs/min (wire length less than 600) |

|

Processing wire diameter |

0.3mm²-1mm² |

|

Cutting length |

100mm- 600mm |

|

Cutting accuracy |

0.5mm + cutting length * 0.2% or less |

|

Stripping length |

1mm-8mm thread end without stripping |

|

PVC pipe length |

40mm shorter than wire length |

|

Heat shrinkable tube length |

25mm (special can be customized) |

|

Pressing ability |

2.0TSpecific |

|

Testing device |

Whether the terminal is crimped, the lack of wire is knotted, whether the pipe is detected, and the pressure management device. |

| air pressure |

About 0.6-0.7Mpa (please use clean and dry air source) |

|

Dimensions |

4000L* 2500W* 1600H (mm) |

| weight |

about 1500Kg |

|

other |

Optional terminal visual inspection (special requirements can be customized) |