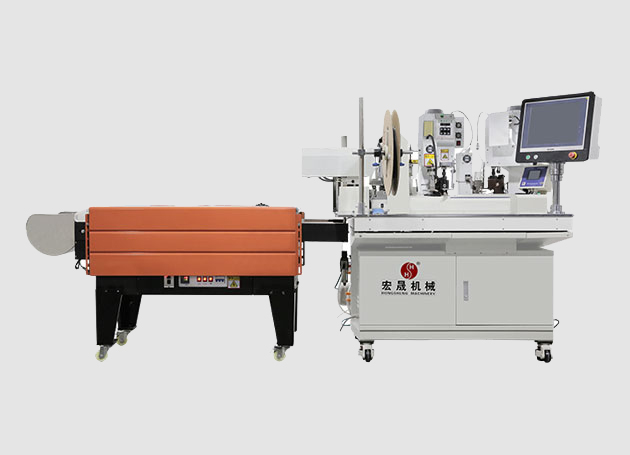

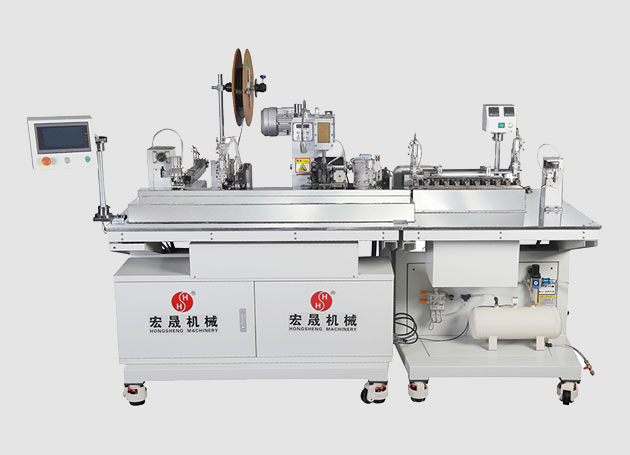

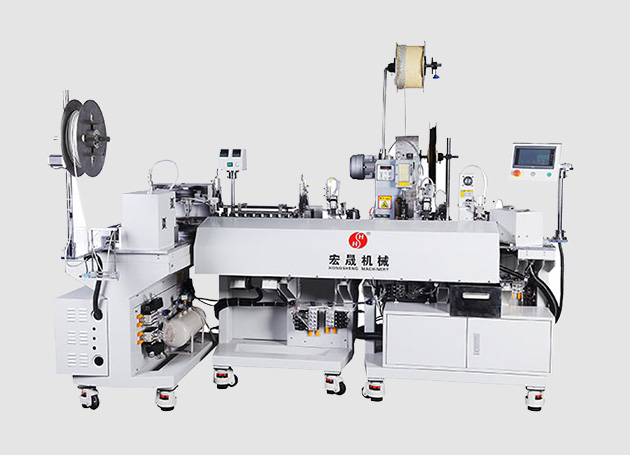

Product name: HS-61216-H single-pressure double-through heat shrinkable tube machine

Product Features

●The equipment realizes continuous automatic processing of wire feeding through wire feeding wheel, cutting off stripping head, single-end crimping terminal and wearing sleeve of heat shrinkable sleeve and wire, and putting a sleeve of 100~150mm long heat shrinkable sleeve on it.

● The wire is stripped and stripped at the end, two different lengths of heat shrinkable sleeves are worn at different positions, and the heat shrinkage is fully automated. The single machine capacity is equivalent to the capacity of a semi-automatic production line of 10 to 12 people.

● PLC control, touch screen operation, simple operation and quick adjustment.

●The main components of the equipment adopt well-known international and domestic brands to ensure the reliability and service life of the equipment.

|

model |

HS-61216-H |

|

power supply |

AC220V/50HZ Single phase |

|

Features |

Single-end crimp terminal, single/double sleeve heat shrinkable sleeve |

|

Production capacity |

18 lines/minute (line length 350mm) |

|

Processing wire diameter |

0.5mm²- 1.5mm² |

|

Cutting length |

300mm- -500mm (set of two sleeves/- length of sleeve wire) 60~ 2000mm (without casing wire length) |

|

Stripping length |

1mm- 10mm |

|

Cutting length |

Pipe 1: 18mm--25mm (pipe 1); Pipe 2: 100~150mm (pipe 2) |

|

Cutting accuracy |

0.5mm + cutting length * 0.2% or less |

|

air pressure |

0.6-0.7Mpa (please use clean and dry air source) |

|

Testing device |

Wire missing or knotted, terminal detection, bushing detection |

|

Heat shrink device |

Hot air pipe + hot drying tunnel |

|

Dimensions |

2100L* 1200W*1650H (mm) ( Without pay-off rack and hot drying tunnel) |

|

volume and weight |

about 450Kg |

| other |

Optional terminal pressure management device, terminal visual inspection |