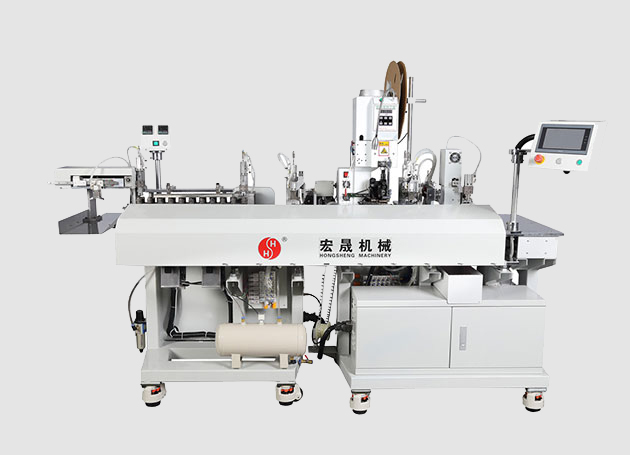

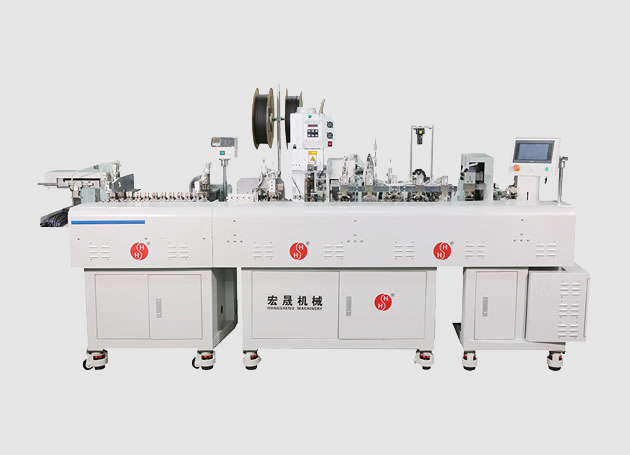

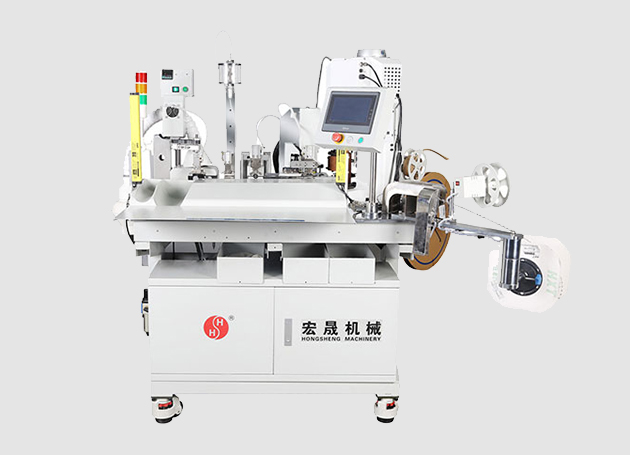

Product name: HS-68216-A round sheathed wire stripping head through end heat shrinkable tube machine

Product Features

●This equipment realizes the first automatic wire feeding of two-core round sheathed wire in China, which is continuous automatic change processing of stripping the outer end, stripping the outer end, stripping the endothelium and playing the terminal sleeve heat shrink tube and then heat shrinking;

● The equipment mainly uses servo motors, with precise action, simple operation, stable performance, labor saving, and quality stability;

●Using touch man-machine interface operation, convenient and fast adjustment;

●Using visual inspection, greatly improving the quality and stability of the product;

|

model |

HS-68216-A |

|

power supply |

AC220V 50HZ ( Simplex) |

|

Features |

The front end is peeled and the rear end is played with two identical spring terminals and sleeved with heat shrinkable tubes (heat shrinkable tubes are automatically sent, cut, sleeved, and heat shrinkable) |

|

Production capacity |

15 pieces/min (wire 100mm-450mm) |

|

Processing wire diameter |

2x0.75mm2 (round sheathed wire) |

|

Cutting length |

100mm-1500mm |

|

Stripping length |

Before peeling 0-60mm, more than 15mm can only be peeled half-back 33-38mm, after peeling the endothelium 30-38mm, |

| Heat shrinkable tube length |

25mm |

|

Pressing ability |

2.0T |

|

Testing device |

Visual inspection (wire leveling), lack of wire knotting, terminal detection |

|

air pressure |

0.6-0.7Mpa (Please use clean and dry air source) |

|

Dimensions |

4000L* 2500W*1600H (mm) |

|

weight |

about 1600kg |

|

other |

Optional pressure management device, terminal visual inspection (other requirements can be customized) |