|

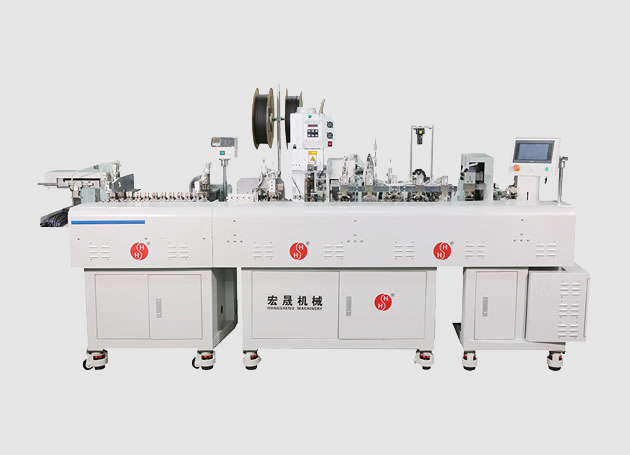

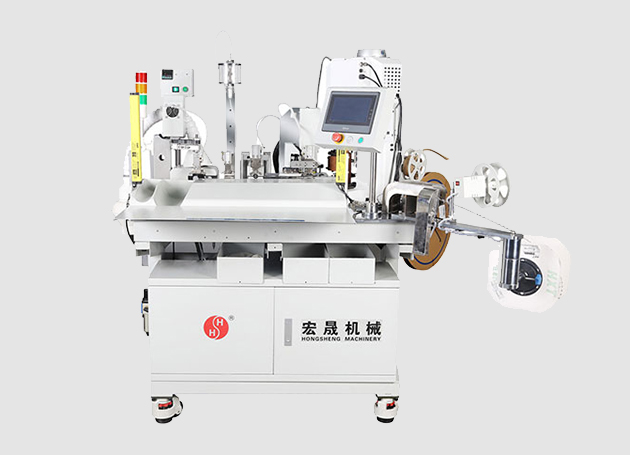

●Single-end wearing waterproof plug and crimping terminal, using waterproof plug first and then stripping head technology, to eliminate the phenomenon of reverse thread wearing waterproof plug; ●Single-end rubbing wire is immersed in tin. According to different wire materials, the wire rubbing function can be set to start and stop. The wire is turned 90° and the tin is dipped vertically, which is even and beautiful; |

| Model |

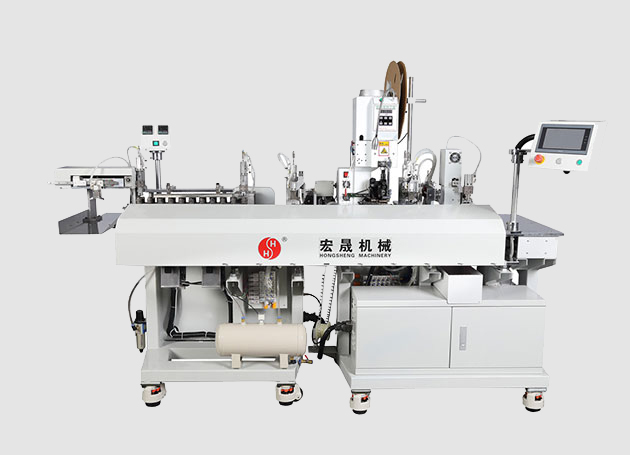

HS-63212 |

|

power supply |

AC220V/50HZ (Simplex) |

|

Features |

The wire is cut off, the single and double ends are peeled, the single end is pressed through the waterproof plug, and the single end twisted wire is dipped in tin |

| Production capacity |

23 lines/min (line length within 500mm) |

|

Processing wire diameter |

0.3mm² -2.5mm² |

|

Cutting length |

55mm- 3000mm |

| Stripping length | 4mm-10mm |

|

Length of thread rolling |

3mm- 10mm |

| Cutting accuracy |

0.5mm + cutting length * 0.2% or less |

|

Pressing ability |

2.0T |

|

air pressure |

0.6-0.7Mpa (please use clean and dry air source) |

|

Testing device |

Wire missing or knotted, end detection, waterproof plug detection |

|

Dimensions |

2200L*3200W*1600H (mm) |

|

Weight |

约400kg |

|

Other |

Optional terminal pressure management device, terminal visual inspection |